Automotive

EZMetrology’s products and systems are used to support the Automotive industry in the development of the quality and innovation of their cars. Our machines provide invaluable data about the behavior of various parts which influences the manufacturing process in ensuring any questions about safety or quality. This includes the interior and exterior parts of the car, as well as the car in its entirety.

K&C on Track

Accurate spindle position data can be collected for driving events on the track. Depending on the scope of the research different characteristics can be extracted:

Maximum – Minimum Vertical or Horizontal Travel (kinematics) Camber in Function of Z Position (kinematics)

Maximum Vertical Travel Speed (damper)

Deflection under brake (compliance)

Combined with a wheel force transducer, the system can provide load vs displacement curve establishing the Kinematics and compliance of the suspension assembly.

Tire Profile

SealScan is a mobile 2D laser scanner to capture rapidly a cross section of a tire, all the way from the inside rim to the outside rim.

Standard Report:

An autogenerated report contain all tables and graphs gathered from the scan, to be used for a comprehensive understanding.

Tire inspection:

Tire deformation under pressure

Wear Pattern

Wheel Clearance

Measuring the required Clearance

Design recommendations to body and suspension specifications can be adjusted to avoid interference between tire and sheet metal.

Minimizing the distance will allow the car to have better stability, but enough distance must be kept avoiding scratches or causing damage to the car.

Combining all trajectories

A test will generate a specific point where maximum vertical displacement, combined with maximum steer and maximum braking will generate an extreme point.

Other tests will reach a maximum in other locations.

All wheel positions combined; the CAD software will determine in which envelope the tire is moving

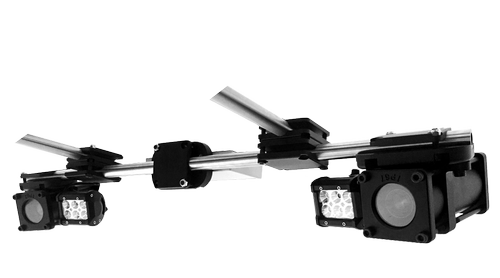

Automated Door System

Our EZSpeed devices can be easily mounted on all door types: Pivot Door, Sliding Door, Power Door, Sliding/Pocket Doors, Trunk/Frunk Tailgate/Lift Gate Roll Up

Applications

Map response time

Map Control Loops

Review Regulator performance

Electrification is a new tool that is compatible with any other door sensor to map and record the electric or electronic interface. This will enable to observe delays, response times between physical events and drive system. EZMetrology initiated OEM driven development project

Advantages

Capture Response Time

Synchronize between Force, Speed, pressure signals

Monitor Electrical Triggers

Monitor System Regulation Mechanism

Seal Gap

SealScan is a non-contact section measurement system. The lightweight 3-axis articulated arm can be mounted on any surface and its patented symmetrical design allows to capture both sides of mating elements to determine the seal gap and seal interference.

Applications

Capture 2D cross section from mating surfaces

Seal fitting and interference.

Window Sill Alignment

Trim Geometry and positioning

Seal Geometry and positioning

Advantages

True Seal Gap Including Door Deformation due to seal load

Non-destructive testing.

No requirement to lock the body

Easy of Use Hard and Software

2D section dimensioning and aligning

Free form Seal Gap

Compare to Cad section

Obstruction measurement

EZPinch can be placed at a distance from flush to simulate an obstruction. In this scenario, there is often no seal compression, and only involves the overall actuator.

In this application, the sensor is placed between body and closure during the final moments. The remaining gap will be approximately 20mm.

Sliding Doors

Following this study EZMetrology is confident the SpeedPod technology can measure the performance of the sliding door while meeting all requirements for an in-line solution.

Cycle Time per door under 30sec

Fast, Operator friendly installation

Go/No-go functionality

Objective and User independent

Wireless Operation and Datalogging.

Fixture Adjustment

From the initial state, a snapshot can be taken for every movement and the 3D evolution of the adjustment can be observed. The operator can focus on the mechanical adjustment.

Once the system confirms that the current position matches the desired adjustment the operation is completed.

Load Case Study

Take snapshot under different load conditions and establish the 3D deformation of multiple points on the structure.

At the end, a final capture can establish if there was any plastic or permanent deformation of the structure during the test.

Results can be an accurate deflection curve in function of the force

Interior Flush and Gap

Observe kinematic behavior and fit of moving parts such as glove compartment, console cover…

To document the quality, look and feel of the interior for different configurations:

Durability Tests

Temperature Influence

Exterior Flush and Gap

Observe kinematic behavior and fit of moving parts such as glove compartment, console cover… Gas / Charging cover, doors or compartments

To document the quality, look and feel of the interior for different configurations:

Durability Tests

Temperature Influence

Mini/Micro Mechanics

Measure and quantify the behavior of mechanical system in the assembly

Fit and Finish

Repeatability

Durability

Travel of System

Loose Play or Deflection

Pressurization

Measure and quantify the deformation under the influence of pressure levels for

Assemblies and their flush and gaps

Cabin Pressure Propagation

Transient Pressure Effects while Driving

Static Deformation

Camera-based 3D measurement system to determine deformation, drift, misalignment of parts or assemblies during test cycles.

Applications:

Flush and Gap drift in Climate chambers

Deformation under static load or pressure

Progressive and fixture adjustment

Advantages:

Easy to use picture based system

Tablet operated

Gap, Flush and Sheer monitoring

Real Time Results

Rugged, for extreme climate

Typical application are Door Handles, Trays, Cabinets, Cabinet Handles, Cup Holders, Coverings.

SealScan

SealScan is a compact, lightweight, 2D scanning system for fast and accurate measurement of cross section mating surfaces. Seal gap, seal compression and panel alignment are the most popular applications.

Features

Measure with all components installed and under real load conditions.

Capture any free form surfaces including seal, mounting flange, corner seals, push-over seals.

Flexible suction cup base, Battery or Grid Powered operation.

Results are shown in real time to avoid gaps or holes in the data set.

Processing and dimensioning in a 2D environment to mimic blueprint.

EZ3D

EZ | 3D is an innovative camera system that utilizes a simple “point-and-shoot” interface to measure relative surface part assembly deformations, all within a standalone handheld device. Measures gap/flush/sheer evolutions during climate test, load test of a structure or assembly.

Features

Easy to use

Uses HD cameras

Faster and more accurate than other gauges

Measures in three dimensions at once

Touchscreen

Handheld

Import/export automated recording

Point-and-shoot

Adhesive targets

Use in dark and light areas

Measure several points in a single snapshot

Intuitive work flow

EZMotion Tire/Wheel

EZMotion system is used to measure vehicle dynamics for wheel or engine motion while driving. The system is capable of tracking 6 degrees of motion with the wheel, engine, and other vehicle components. This data can be used to, Optimize Tire Characteristics, Improve Simulation models (Input or Validate), Suspension Geometry Study (Kinematics & Compliance), Develop Drive Files for test benches, and Suspension Damper/Spring Tuning.

Features

Optimized image processing for reliable measurements in all road and test conditions.

Simplified and secure mounting systems.

Easy to operate touch screen interface for system manipulation and data recording while operating the vehicle.

Interfaces to wheel force transducers [ask us for compatibility].

Possibility to synchronize with 3rd party sensors.

One platform to measure both wheel and/or engine movement up to 500hz.

Raw or unfiltered data available in text format for post processing.

Real-time feedback while recording.

Unlimited recording time.

Accurate 3 and 6 dimensional measurements and not estimated.

Limited overhang compact mounting for easy maneuvering for test facility environment.

EZMotion IP68

A solution for 3D kinematic inspections in rugged environments. It is used to inspect travel, speed, stability, structural stiffness, and dynamic response of assemblies. Multiple systems can be combined to cover large areas with unprecedented accuracy. Available for different speed and volume configurations.

Features

Measure anything from slow deflections or displacements all the way up to higher mechanical vibrations even beyond the 2000Hz band.

Different trackers to track objects in 3D (XYZ) or 6D (XYZIJK) from adhesive targets to rugged mechanical targets.

Networking of camera systems for big structures or wind tunnel testing.

Modularity to select the camera resolution and fixture adjusted to the customer application.

Real-time feedback with EZMotion Software

Robust and industrial grade for challenging environment

EZMotion Portable

EZMotion Portable is a 3D or 6D measuring system based on latest stereo vision camera technology. This variant of the technology is designed for portable use where the system can be transported and installed on-site in a minimum amount of time. The system is capable of tracking a multitude of points or objects in space and determining their absolute or relative movement through advanced on-board software.

Features

Stereo Vision Technology for high accuracy

Passive Optical Trackers for 3D Position or 6D Position/Angle measurement

Unlimited recording time

Rugged, light weight and solid-state system

Different Volume/Accuracy/Speed, configurations available to meet requirements

IP68 Option

Camera Network Option for large volume, high accuracy

SpeedPod

With thousands of satisfied users, EZMetrology has consolidated all feedback, updated and developed the next generation gauge.SpeedPod stands for innovation on many levels, like; Improved Accuracy, Reduced Measurement Time, Simplified Operation, Reduced Size and Weight (250gr), and Connectivity.

Features

Create and manage door profiles

Define Target Values and Nominal

Active different measurement Modes

Set up Network Configuration

Firmware Upgrades

EZSpeed

EZSpeed is the next generation velocity gauge. It is a compact unit system that mounts via a vacuum cup on the body. EZSpeed measures the speed of the door while closing and calculates the minimum closing speed. It takes only a few seconds to install. It will report results on the screen or to the software via an optional wireless link.

Features

ONE Single Independent Unit

Automatic Rotation Function for screen with device orientation

Tolerances

Removable Rechargeable Battery

Charger up to 8h on single charge

For real-time data display

EZPressure

EZPressure is a device developed to accurately measure and track the pressure inside of a cabin during a door closing event. It is a valuable add-on to the line of EZ Metrology door inspection gauges because it records the rapid pressure variation that occurs and the important characteristics of the waveform on its display.

Features

Pre-determined peak detection algorithm

Wave Characteristics: Peak and Vacuum level, rise and drop time

Synchronization in and output

Units: mbar, Pa and mmH20

Sleep mode for extended battery life

LED lights indicator during testing

Exchangeable Lithium-Ion battery for continuous operation, with desktop charger

Can be combined with other EZ devices from the EZDoorkit

The pressure sensing point can be extended using tubing to record the pressure wave at precise, remote or confined place

EZSlam

The EZSlam innovative design measures and stores door closing data for the complete closing event. EZSlam integrates precise algorithms and scientific methods into a simple, comprehensive tool for closure measurement. EZSlam translates subjective impressions into objective numbers. It is easy to use and can be operated by non-metrology technicians.

Features

Easy to use

Compact to transport

Reduced testing time

Increased accuracy

All-in-one measurement

Low maintenance

Wireless operation

EZEnergy

EZEnergy is a compact device that can be easily installed on any closure, and it will allow the user to capture how much energy he had to apply to the door in order to bring it to a close. The advantage of measuring the energy is that it will also include the effect of check and hinge while classic speed devices only capture the influence of seal and latch.

Features

Advanced algorithms for best accuracy and optimal repeatability

Non-abrasive suction cup mount, with quick release

Compact and light stand-alone measurement device: no wires, computer datalogger or external power required

Sleep Mode for extended operations

Bright, scratch proof, multifunctional display with autorotate function

Comes in rugged transport case with desktop charger and battery

Would you like to learn more about our products or services? We are happy to provide you with more information.